-

Flour

correctionFlour correction

Discover

DiscoverFlour correctors are concentrated technological and/or sensory ingredients that enable the functional profile of flours to be optimised according to the applications required by millers.

- Improvers

Industry and Craft bakeryImprovers Industry and Craft bakery

Discover

DiscoverImprovers (or additives) used in breadmaking are technical concentrates that facilitate the work of bakery professionals and make it safer by correcting how dough behaves throughout the breadmaking process.

- Creation

Mixes and ConcentratesCreation Mixes and Concentrates

Discover

DiscoverMixes and Premixes (or concentrates) are breadmaking solutions to allow bakers to make a wide range of special breads, high-taste baguettes, pastry and cake products and sweet buns in a quick and easy manner.

- Customizing

Bakery blendsMILLBÄKER Designer and producer of ingredient solutions for the baking industry

- Industry Solutions

- Milling Solutions

- Craft Bakery solutions

- Details

- Hits: 14332

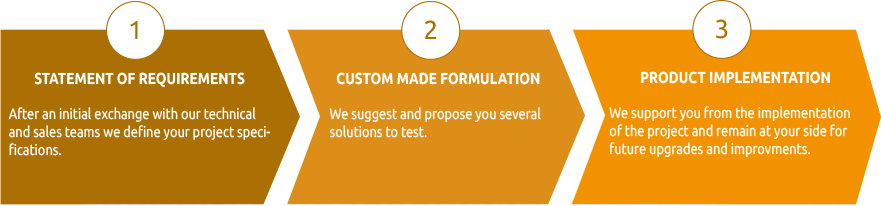

Custom-made formulations

Unique, personalised solutions

MILLBÄKER stands out for its ability to create personalised technical, sensory and nutritional solutions to meet the expectations and specifications of its clients.

Our custom-made solutions

MILLBÄKER already has over 1 500 concentrate formulations subject to special, confidential specifications.

Our following range of personalised products meets the expectations of our clients in the flour industry:

- Flour correctors: Solutions enabling you to balance the technological and sensory profile of flour.

- Artisan bakery improvers: Solutions to help make your work in the bakery easier because they adapt to your working methods and the products you use.

- Improvers for industrial baking: Technical solutions for optimising the behaviour of dough, productivity of the lines and the results of the finished products for the baking industry.

- Mixes and Premixes for bakeries, confectionery, pastry-making:

- Solutions enabling you to create personalised baking products:

- New own brand product concept

- Specific sensory properties (association of specific tastes/textures)

- Nutritional and ethical justifications (source of fibre, proteins, omega 3)

- Marketing claims (clean Label, regional product)

How we work

Contact us to create your very own personalised product

- Details

- Hits: 8265

Mixing Centre

Personalised ingredient mixing

Performance and Responsiveness

Conceived as part of our innovation policy, our Mixing Centre enables us to create a huge range of baking products from over 1 500 ingredient resources.

Located at our site in Torcy le Petit (10), our double mixing station was designed to respond to our policy of flexibility and responsiveness.

- Flexible solutions: batches from 200 kg to 1 tonne, from sacks to big bags, we stand out for our ability to provide a solution for every market.

- An evolving tool: as the expectations of our clients, consumers and the market change, so does our Mixing Centre. It has been certified since 2014 for making organic products (certified by Ecocert). Our innovation policy was further boosted in 2015 by the installation of a line dedicated to the injection of fluids.

- The complementarity of our production and Quality Centres: Our Mixing Centre protects the safety of the product and the consumer through the various stages of the production process. Allergen risk management, traceability and FIFO compliance are rigorously implemented and monitored during the production process.

- Integrated programming of mixes

- Full traceability from raw material to finished product

- Compliance with allergenicity rules

- Flexible, advanced tool

- Tool for custom-made products

- Details

- Hits: 636

Le fournil d'essai

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Proin ex risus, lobortis id ultrices in, ultricies ut nunc. Aenean sit amet scelerisque nisl, ac pharetra justo. Sed hendrerit, lectus ut consequat cursus, lectus ipsum consequat leo, sit amet fermentum leo nulla non odio. Vivamus aliquam sapien urna, sit amet lobortis nibh sollicitudin quis. In ac vehicula nulla. Quisque non nibh id libero porta convallis id vitae est. Pellentesque et tincidunt quam. Phasellus mollis pretium erat, sit amet gravida ex suscipit ut. Curabitur euismod, quam euismod malesuada luctus, urna odio vehicula urna, non sodales sem nisl vel lorem. Integer dapibus, orci vitae semper sagittis, dui lacus scelerisque massa, condimentum sollicitudin massa turpis mattis quam. Nulla nec metus vitae tortor rhoncus semper ut at nibh. Mauris at dolor dolor. Aenean quis consequat erat. Aenean interdum tellus odio, a dapibus diam dignissim ac. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos.

Aliquam eleifend pulvinar quam eget posuere. Maecenas posuere cursus dui in luctus. Phasellus viverra pharetra nisi. Donec sit amet elit fringilla, lacinia erat finibus, vehicula quam. Nam luctus venenatis nulla, vitae suscipit neque sollicitudin eu. Nulla suscipit neque sapien, quis aliquet ipsum eleifend non. Nulla tincidunt posuere molestie. Nullam eu bibendum eros. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Quisque auctor nunc sit amet leo feugiat, laoreet auctor mauris molestie. In euismod quis nisl semper vestibulum. Nulla accumsan erat et leo condimentum, nec mollis mauris dapibus. Pellentesque libero arcu, mattis sed diam at, viverra congue nulla. Nullam porttitor tristique sem, sed mollis velit lobortis id. Vivamus quis imperdiet quam.

Ut nibh enim, scelerisque nec molestie ut, ullamcorper facilisis justo. Integer odio purus, luctus eget leo non, lacinia faucibus mi. Quisque ac quam non ligula hendrerit finibus vel a arcu. Morbi in lobortis ante. Integer augue erat, sollicitudin vel vehicula ut, interdum laoreet orci. Nam convallis arcu magna, ac finibus elit fringilla aliquet. Sed nec urna vitae erat ultrices lacinia vitae ultricies tellus. Fusce efficitur dignissim tristique. Praesent ut auctor eros, sed aliquet est.

- Details

- Hits: 9750

Technical Centre

3 mutually supportive and complementary areas of expertise

R&D

very year, MILLBÄKER invests 5% of its revenue in R&D.

The work of our R&D teams is structured around the following subjects:- Organoleptic work: Maximizing the potential of ingredients with the aim of developing new sensory pallets(e.g.: speciality breads with new textures and flavours, inclusion products etc.).

- Technological work: Working on the technological properties of ingredients and their application in baking (e.g.: making products more moist or longer lasting with special enzymes).

- Innovation: Creating innovative, trend-setting formulations.

(e.g.: introducing Clean Label products without additives or preservatives; creation of gluten-free preparations etc.).

Baking Centre

Our Baking Centre enables our team of technical experts to develop and check our formulations by reproducing real artisan and industrial baking conditions.

The everyday job of our bakers consists of the following:

- Conducting baking checks on samples of wheat and flour sent on a daily basis by our clients.

- Working together with the R&D team to develop tomorrow’s products for the bakery.

Within this framework, our Baking Centre is Research Tax Credit approved by the Ministry of Higher Education and Research - Validating that industrial productions comply with specifications.

- Conduct technical training with clients and their sales teams on specific products and ingredients.

Within this framework, our Technical Centre is an approved training centre by the French Ministry of the Economy, Industry and Employment.

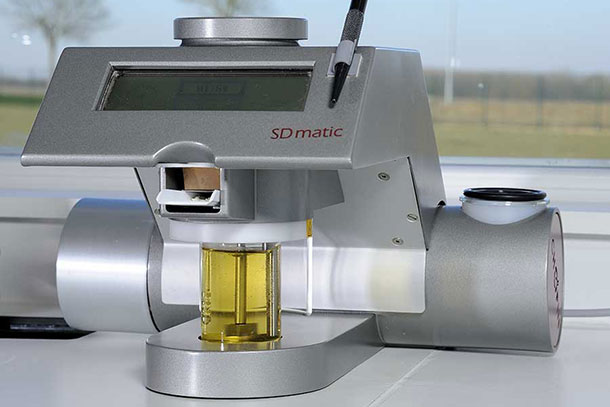

Physical/chemical test laboratories

Teams at our laboratory conduct personalised tests based on our clients’ needs and background, using state of the art equipment.

Each year over 5000 wheat and flour tests are conducted to:

- Monitor wheat and flour quality to establish what corrections are required to maintain their consistency.

- Provide our clients with personalised technical support, where necessary (wheat models, flour correction etc.).

ACTUALITÉS MILLBÄKER EN

-

-

06 2023L'Abricotière

The combination between apricot and rosemary

-

-

-

06 2022Sando

Japanese toast bread

-

Innovation MILLBÄKER EN

MILLBÄKER

INNOVATIVE INDUSTRYDeveloping and maximizing the potential of ingredients and their synergies is our daily mission.

From the raw material stage up to turnkey designs, we provide support for your markets through high quality and reliable performance.Découverte produits Millbaker

Use of Cookies

By continuing your navigation without changing your settings, you accept the use of cookies. For more information, manage or change the settings, click here - Improvers